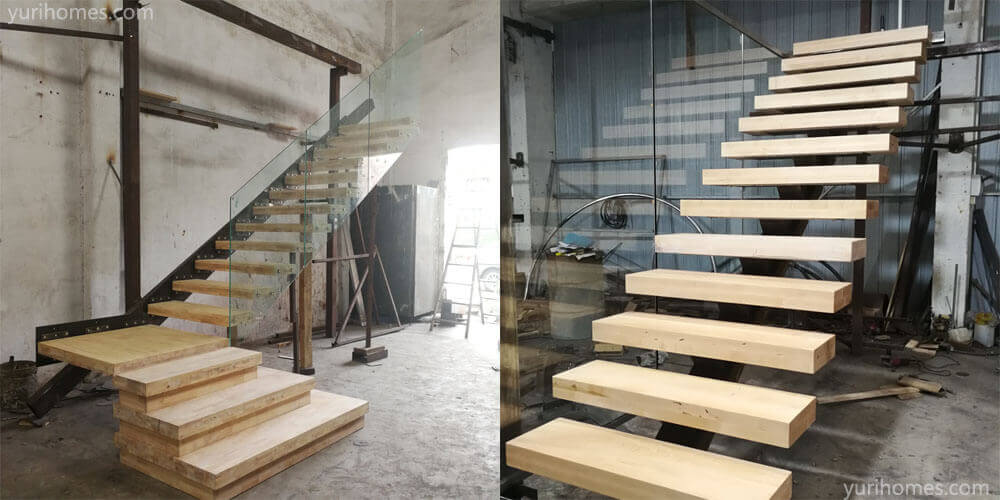

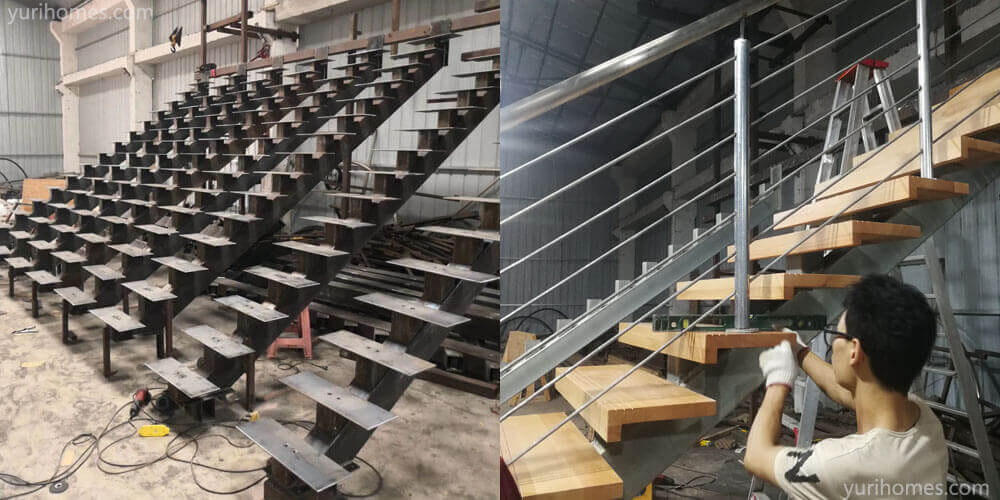

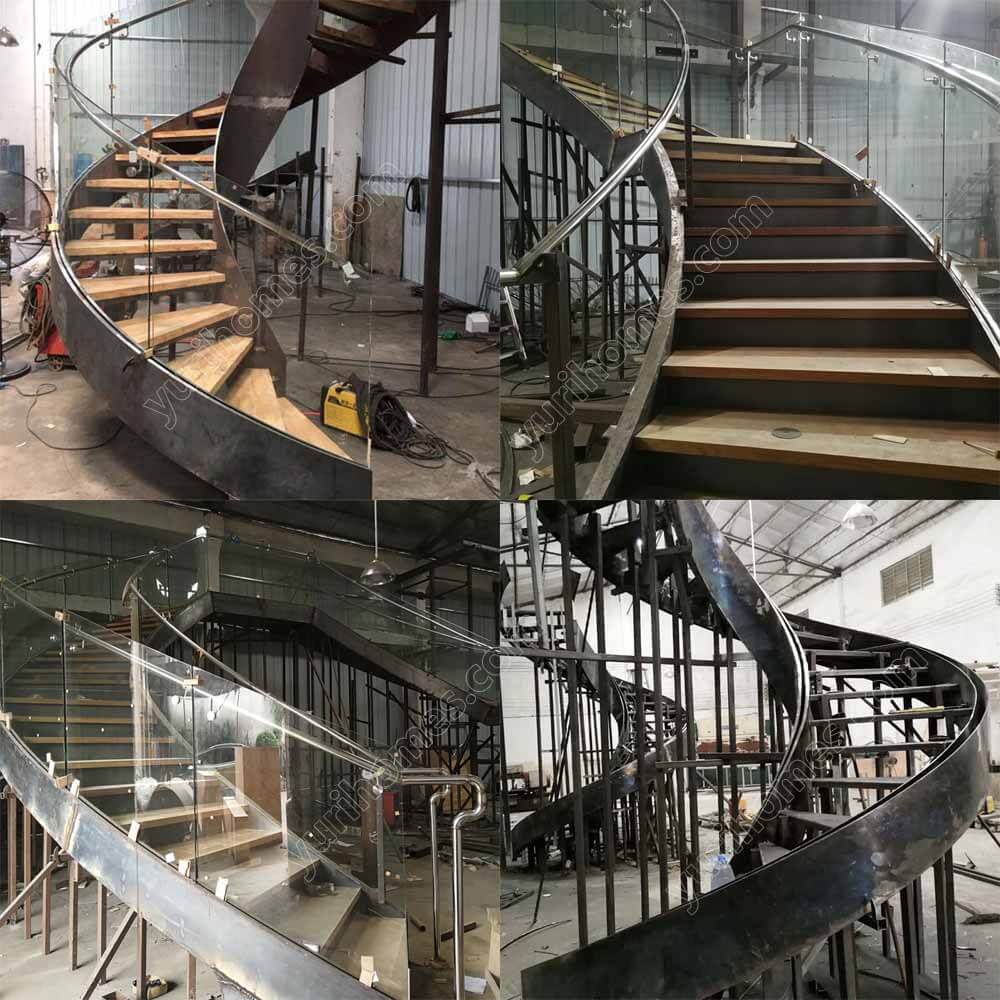

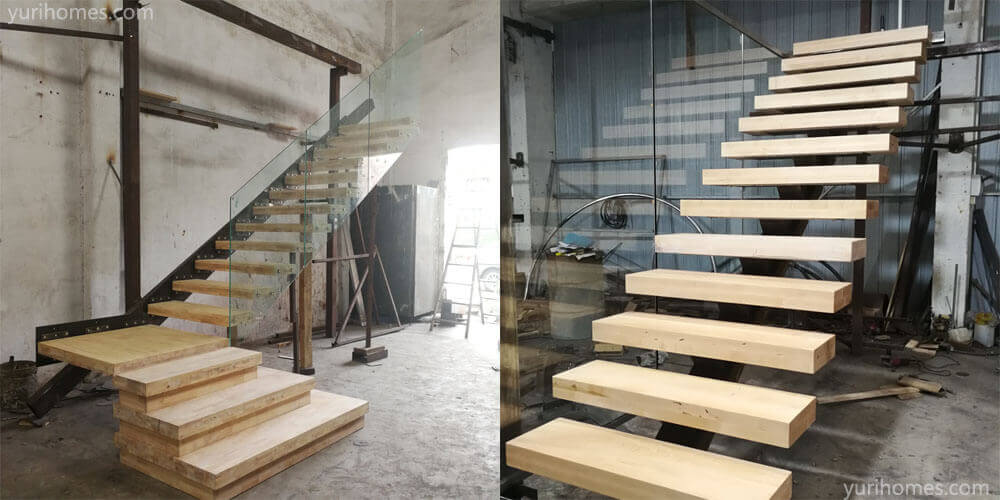

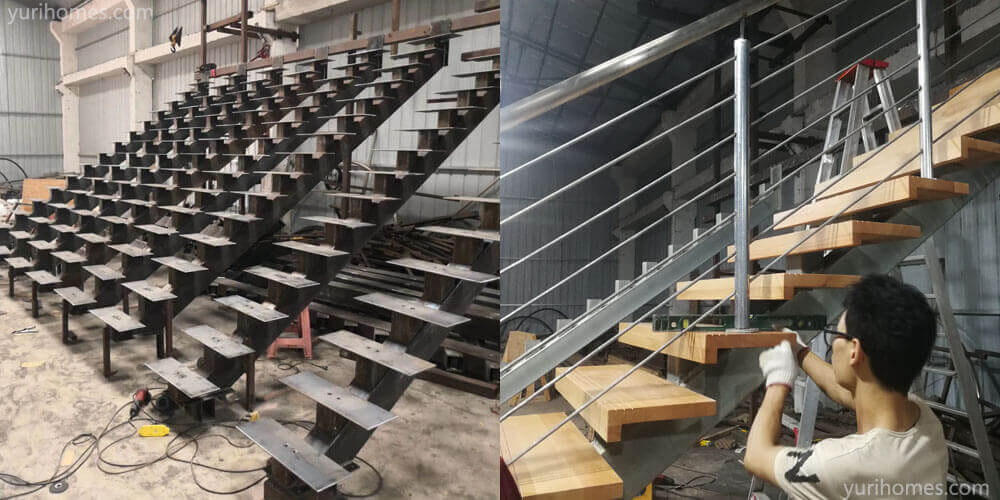

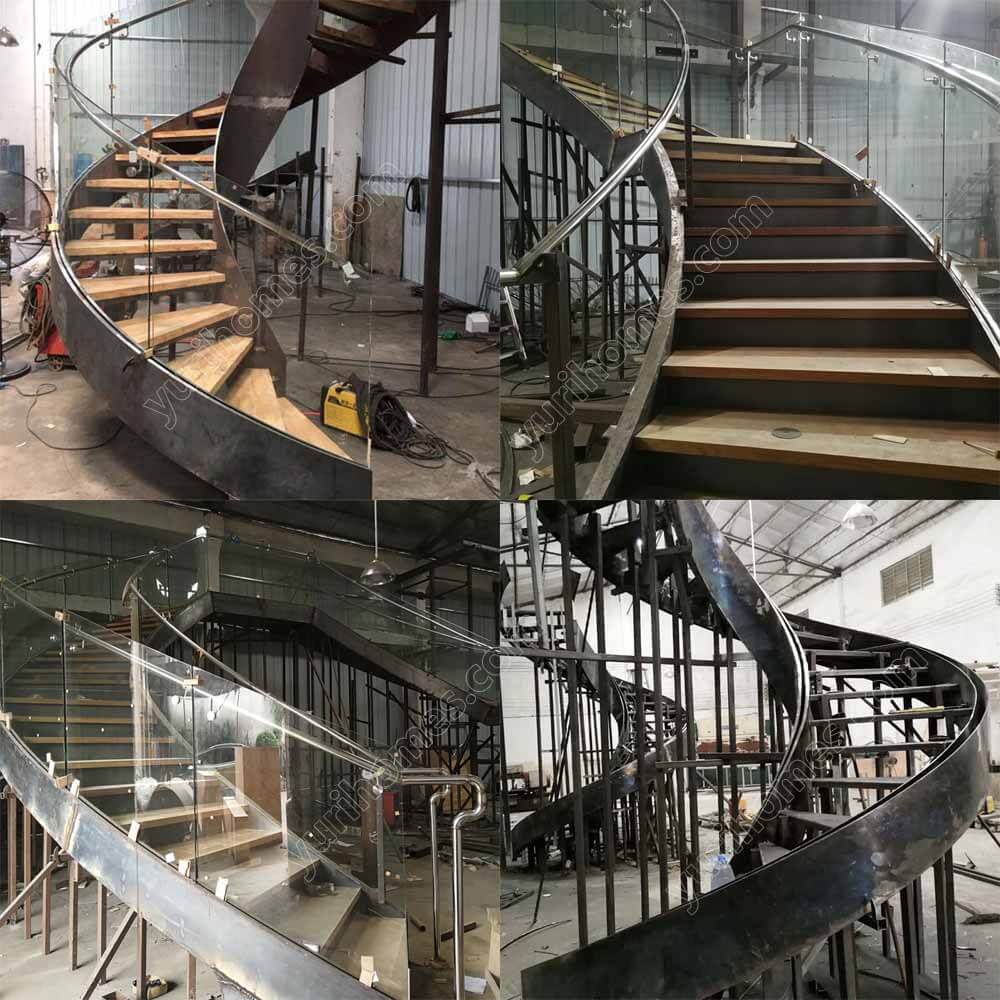

We will do the trail assembly when all parts of the staircase are ready to check all parts are fit well and the actual measurements are consistent with the design dimensions.

Email: info@yurihomes.com

We will do the trail assembly when all parts of the staircase are ready to check all parts are fit well and the actual measurements are consistent with the design dimensions.

The wooden treads of staircases are made by ourselves, Thailand splicing oak is the most commonly used, and there are other materials for options such as European beech wood, American white oak, American red oak, American hard maple, Burma teak wood, rose wood, merbau wood, ashtree wood, sapele wood. The thickness is between 20mm~ 160mm and we can do a lot of custom shapes.

Staircases are customized products, so each production is different, each time requires workers to craft carefully.

This room is used for painting metal surface, such as metal stringer, metal tread support plates and other metal parts, there is a large oven over 5 meters in length.

When the wooden treads are ready, we do the surface treatment, here are the color options:

Workshop for wooden tread surface treatment:

We make strong plywood crate for protecting staircase and glass.